In a world where sustainable solutions are more important than ever, Beston Group stands out as a global leader in the development and manufacturing of advanced pyrolysis systems. The company is committed to transforming waste into valuable resources through cutting-edge thermal decomposition technology. With years of experience and innovation, Beston Group offers reliable equipment, comprehensive support, and tailor-made solutions to meet the unique needs of clients across various industries.

What Is Pyrolysis and Why It Matters

Pyrolysis is a thermal process that breaks down organic materials in the absence of oxygen. This method is used to convert waste such as plastic, rubber, sludge, and biomass into fuel oil, carbon black, and combustible gas. Not only does this reduce the amount of waste that ends up in landfills or incinerators, but it also helps generate useful byproducts that can be reused or sold.

Beston Group has played a crucial role in promoting this technology globally. By leveraging years of R&D and manufacturing expertise, they offer some of the most efficient and environmentally friendly pyrolysis systems on the market.

Why Choose Beston Group for Pyrolysis Equipment

One of the biggest reasons clients choose Beston Group is their end-to-end support. From feasibility analysis to installation and after-sales service, Beston provides comprehensive project guidance to ensure success. Their equipment is known for safety, high efficiency, and low emissions, all of which align with today’s environmental standards.

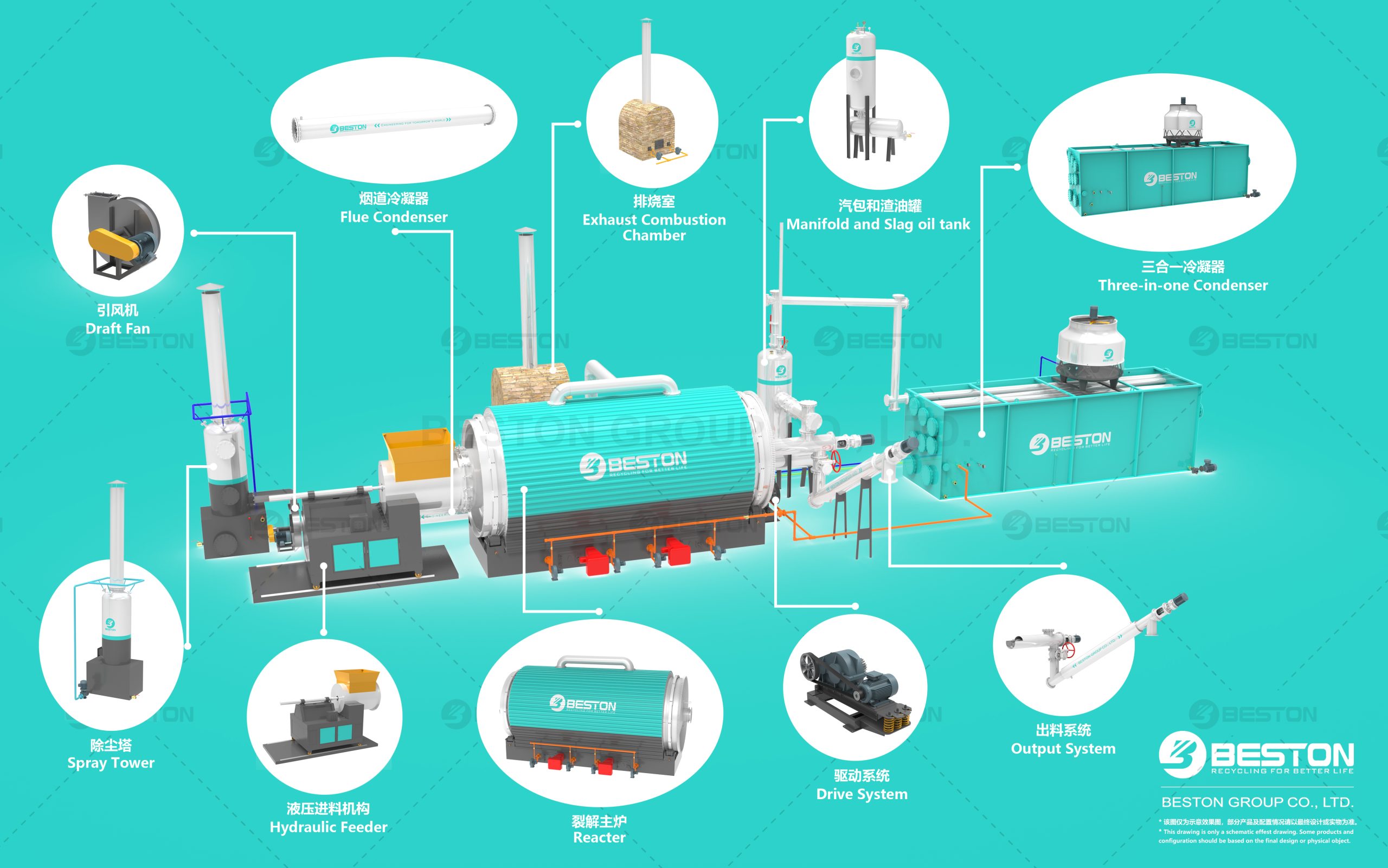

Moreover, Beston offers flexibility in design, allowing clients to choose between batch, semi-continuous, and continuous pyrolysis plant models based on operational needs and budget. Each unit is equipped with advanced automation systems that simplify operation and enhance productivity.

Understanding the Investment: Pyrolysis Plant Cost

A common question that arises when considering this technology is the overall pyrolysis plant cost. The price of a pyrolysis plant depends on several factors such as capacity, raw materials, automation level, and local installation requirements.

Beston Group provides detailed cost breakdowns for prospective clients, helping them make informed decisions. While the initial investment may seem substantial, the return on investment is promising due to reduced waste management fees, the value of the end products, and various government subsidies supporting green technology.

Applications Across Multiple Industries

The versatility of pyrolysis technology makes it ideal for a wide range of industries. Plastic recycling plants, tire disposal facilities, sludge treatment centers, and agricultural businesses can all benefit from this solution.

For example, the plastic-to-oil process helps tackle plastic pollution while creating marketable fuel. Similarly, pyrolyzing old tires not only prevents harmful emissions from burning but also yields carbon black and steel wire, which can be reused in manufacturing.

Beston Group customizes each solution based on industry needs. Whether it’s handling municipal waste or agricultural biomass, Beston ensures optimal performance and economic benefit.

Continuous Pyrolysis Plant: Efficiency at Its Best

The continuous pyrolysis plant is a game-changer for businesses aiming for large-scale operations. Unlike batch systems that require downtime for feeding and discharging, the continuous model operates 24/7, dramatically improving throughput and reducing labor costs.

This fully automated system also enhances safety and consistency. With smart temperature and pressure control mechanisms, users can achieve stable production and better-quality outputs. It’s ideal for businesses that need to process tons of waste daily without interruption.

Global Installations and Success Stories

Beston Group has successfully installed pyrolysis plants in over 90 countries, including the UK, Canada, South Africa, Indonesia, Nigeria, and more. Each project serves as a testament to their engineering excellence and customer-centric approach.

Clients often report reduced operating costs, increased profitability, and regulatory compliance after deploying Beston systems. These success stories further strengthen Beston’s position as a trusted brand in the pyrolysis industry.

Eco-Friendly Engineering at Its Core

Environmental protection is at the heart of everything Beston does. Their pyrolysis technology is designed to minimize harmful emissions through advanced filtering systems and sealed feeding/discharging structures. The energy used during the process is often recycled within the system itself, reducing dependency on external fuels.

Beston’s equipment meets CE, ISO, and SGS certifications, ensuring it adheres to international environmental and safety standards. This commitment makes it easier for businesses to align with global sustainability goals.

The Beston Pyrolysis Advantage

Choosing beston pyrolysis means investing in innovation, sustainability, and long-term value. Their strong technical team, in-depth training programs, and prompt after-sales support give clients the confidence to adopt this technology smoothly.

From small enterprises to multinational corporations, customers rely on Beston to deliver durable solutions that perform under various conditions. Their after-sales services include on-site training, remote troubleshooting, and free updates, making them a reliable partner throughout the equipment lifecycle.

Moving Towards a Greener Future

As the world continues to face challenges related to waste management and energy demand, pyrolysis offers a powerful solution to both issues. Beston Group is proud to be at the forefront of this transformation, empowering industries and communities to turn waste into wealth while reducing environmental impact.

If you’re exploring sustainable waste processing options, it’s time to consider the benefits of pyrolysis. Reach out to Beston Group today to learn more about how their technology can fit into your business model and contribute to a cleaner planet.